-

Home

-

Products

-

Household Tape

- Water pipe leak tape

Water pipe leak tape

Water pipe suddenly burst? Joints keep leaking?

When facing urgent leaks, you need a solution that reacts fast and seals permanently. Silicone Leak-Stop Tape uses unique self-fusing technology—no glue required. Simply stretch and wrap to fuse seamlessly, forming an integrated rubber seal layer. Powerful leak-stopping and lasting waterproofing make it the reliable choice for professional repairs and household emergencies.

I.Core Technology & Advantages

1.Self-Fusing Seal: Stronger Without Adhesive

– Automatic Polymerization: During stretching and wrapping, the inner silicone polymers fuse seamlessly, creating a residue-free rubber seal tube that prevents secondary leaks.

– Long-Lasting Waterproofing: The formed seal layer offers exceptional waterproofing, moisture resistance, and chemical corrosion resistance, suitable for prolonged immersion environments.

2.Extreme Environment Durability, Consistent Performance

– UV and Weather Resistance: Engineered for harsh outdoor conditions, withstands sun exposure, rain, extreme cold, and heat without hardening or cracking over time.

– High Tensile Strength and Flexibility: Stretches to over 150% of original length, conforming tightly to irregular shapes like threads, bends, and damaged areas while providing uniform wrap pressure.

3.Multiple colors available for enhanced identification management

– Five-color coding system: Offers distinct black, red, yellow, green, and blue hues for color-coded classification and labeling of piping systems, wiring, or repair zones, boosting maintenance efficiency and safety.

4.Multi-functional versatility for comprehensive emergency repairs

– High-voltage insulation: Delivers electrical insulation strength up to 20KV/mm, suitable for temporary cable repairs and joint protection.

– Versatile application: From water pipes, gas hoses, and automotive fuel lines to outdoor gear and temporary tire patches—one roll addresses multiple leakage crises.

II.Primary Application Scenarios

– Pipe repair: Thread sealing, leak prevention at joints, and emergency crack repair for various metal/plastic water pipes.

– Outdoor & industrial: Waterproof sealing for irrigation systems, pool equipment, marine piping, and compressed air lines.

– Vehicle Maintenance: Emergency leak control for automotive fuel lines, coolant hoses, and A/C lines.

– Home Emergency: Rapid leak stopping for faucet connections, hose joints, and bathroom fixtures.

– Electrical Assistance: Insulation and waterproofing for cable joints, temporary outdoor wiring protection.

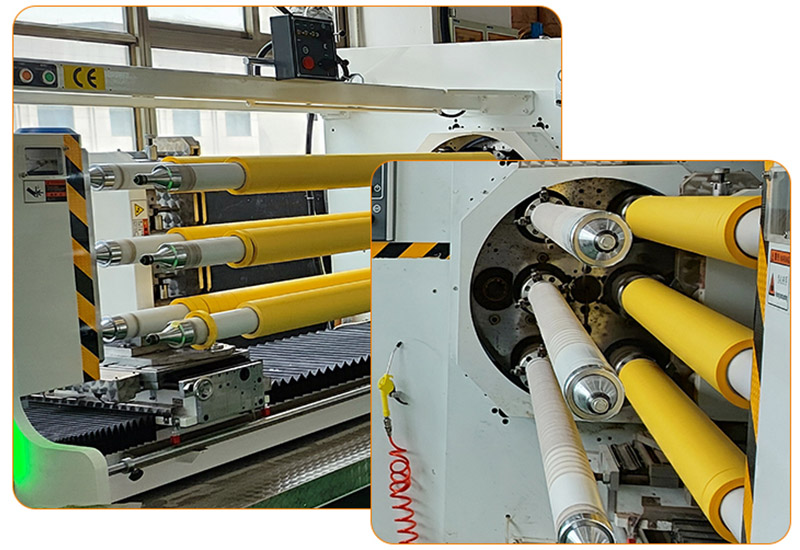

III.Product Specifications & Usage Guide

– Core Material: Self-fusing silicone polymer

– Common Specifications:

– Width: 12mm / 19mm / 25mm

– Length: 1m / 3m / 5m

– Colors: Black, Red, Yellow, Green, Blue (available in single or combination packs)

– Key Parameters: Elongation ≥150%, Insulation Strength ≥20KV/mm, Operating Temperature -60°C to +200°C

Simple Three-Step Application:

1.Preparation: Clean and dry the surface to be sealed, ensuring it is free of oil and dust.

2.Wrap: Stretch the tape to approximately 1.5 times its original length. Apply it tightly in a half-overlap pattern, maintaining even tension.

3.Cure: No additional tools are required after wrapping. Allow several minutes for the tape to self-fuse into a seamless, integrated seal.

IV.Pro Tips

– For pipes under high water pressure, apply multiple layers for optimal pressure resistance.

– This product uses a physical self-fusing process, requiring no open flames or heating tools for safe and convenient application.

– The color-coded series not only enhances aesthetics but is also recommended for distinguishing different media pipes (e.g., cold water, hot water, gas) to establish a safety identification system.

> One roll in hand, not a drop escapes.

> Silicone leak-stop tape isn’t just a patch—it’s your “pressure-proof solution” for sudden leaks, transforming frequent repairs into a permanent fix.

> For model selection based on specific media (water, oil, gas) or pressure ranges, consult our technical support anytime.

-

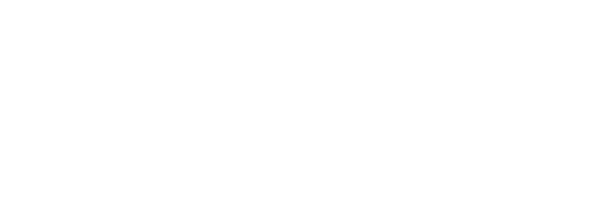

HIGH-QUALITY SILICONE

Good elasticity Waterproof Anti-slip Wear resistance

CANES

RACKET

SPORT

BICYCLE

EQUIPMENT

-

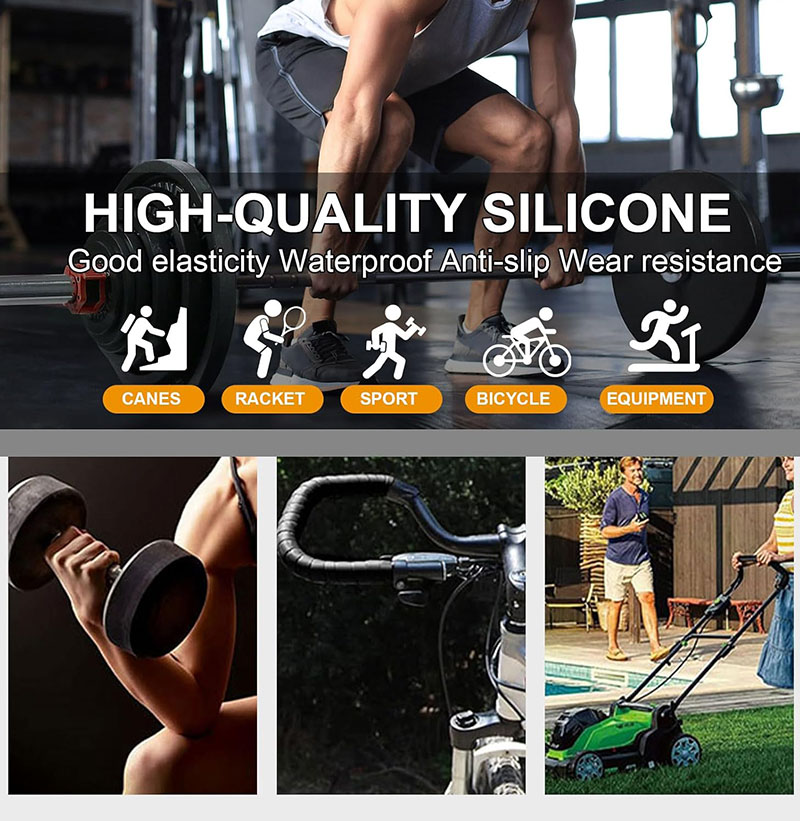

HOW TO USE

Step1:Remove isolation film

Step2:Determine the position

Step3:Intertwine

Step4:Pressure

-

HIGH CONFORMABLE SOFT SILICONE TAPE

Suitable for irregular surfaces

Suitable for home appliance repair

-

Water Leak Repair

Wire insulation

Pipeline Sealing

Electrical Repair

-

Good Temperature Resistance

Short-term maximum heat resistance is260°C(500°F),down to -50°C(-60°F).

Self Fusing

Good Ductility

No Sticky Residue

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

Technical Assistance

Billing and Payment Services

Why Choose Us?