-

Home

-

Products

-

Building & Decoration Tape

- Butyl waterproof tape

Butyl waterproof tape

I.Core Characteristics and Technical Advantages

1.Superior Sealing Performance

Formulated with high-purity butyl rubber featuring a dense molecular structure, this product achieves an extremely low water vapor transmission rate (nearly zero permeability). Combined with the physical barrier effect of the upgraded aluminum foil layer, it completely blocks moisture and gas penetration pathways, significantly outperforming traditional asphalt-based or PVC tapes. Test data shows a 40%+ increase in adhesive peel strength, ensuring lasting seals at critical locations like roof joints and pipe interfaces.

2.Extreme Environmental Tolerance

Outstanding Weather Resistance: The aluminum coating effectively reflects UV radiation. Combined with butyl rubber’s inherent antioxidant formulation, it withstands extreme temperature cycles from -40°C to 80°C. Performance remains stable under diverse climatic conditions including salt spray, humidity, and arid environments. High Chemical Stability: Exhibits excellent resistance to acids, alkalis, and common solvents, making it suitable for sealing pipelines in chemical zones and industrial facilities.

Safe and Eco-Friendly: Completely solvent-free, compliant with RoHS environmental standards. Non-toxic and odorless, safe for direct contact with drinking water systems (e.g., sprinkler systems) and enclosed spaces (e.g., RV interiors), ensuring user health and safety.

3.Wide Substrate Compatibility

With high initial tack and sustained cohesive strength, it securely bonds to surfaces including metals (galvanized steel, aluminum), inorganic materials (concrete, masonry, tiles, glass), synthetic materials (PVC, EPDM rubber, fiberglass), and porous substrates (wood, gypsum board). This overcomes traditional tape limitations on substrates, enabling “one tape for multiple uses.”

II.Diverse Application Scenarios

Leveraging its versatility and reliability, this product has been deeply integrated into the following key sectors:

Building Waterproofing Systems: Rapid roof crack repair, skylight/chimney base sealing, exterior wall joint waterproofing, basement leak remediation. Replaces traditional hot-melt application with 80% efficiency improvement.

Vehicle Maintenance: RV/camper roof canopy repairs, marine deck joint sealing, automotive window/door seal reinforcement, withstanding high-speed wind pressure and wave impacts.

HVAC Engineering: Duct joint sealing, vent leak prevention, air conditioning pipe connection protection, effectively reducing energy consumption.

Pipe System Protection: Emergency crack repair for PVC drain pipes, anti-corrosion wrapping for metal fittings, and leak prevention at irrigation system joints, withstanding water pressure fluctuations.

Outdoor Gear Assurance: Reinforced tent seams, canoe hull leak sealing, and outdoor water container repairs, enhancing equipment reliability in harsh environments.

DIY Innovative Applications: Temporary tarp securing, garden structure joining, household gap filling—flexible operation without specialized tools.

III.Efficient Application Guide

Butyl tape is designed around “convenience and efficiency”:

1.Surface Preparation: Remove surface dust, grease, and loose particles from the substrate. Ensure it is dry and clean (no primer required).

2.Cut and Apply: Trim tape to desired length, peel off release liner, and press directly onto target area.

3.Compress and Set: Apply pressure by hand or roller to ensure full contact between tape and substrate, especially along edges.

4.Environmental Adaptation: Avoid exposure to strong water flow for 24 hours post-application; rapid initial strength development occurs at room temperature.

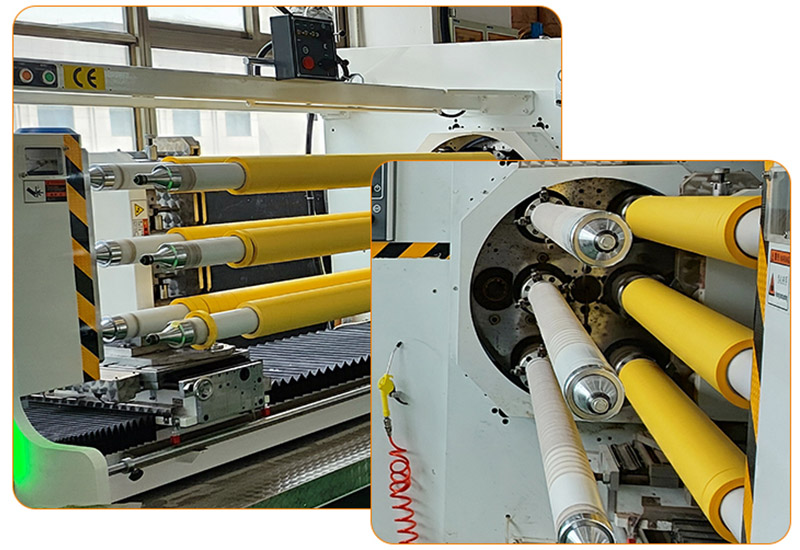

IV.Hongfu Tape Brand Assurance

Hongfu Tape specializes in sealing material R&D and manufacturing. Leveraging advanced polymer laboratories and stringent quality control systems, each roll of butyl tape undergoes:

International Standard Certification: ISO 9001 Quality Management System, ASTM D1970 Waterproofing Test Standard.

Extreme Environment Simulation Testing: 3,000 hours of accelerated UV aging and 30 cycles of high/low temperature (-40°C to 80°C) without failure.

Continuous Technology Iteration: Formulation and aluminum foil composite processes optimized based on global user feedback, with products upgraded to the 5th generation.

Conclusion

Butyl tape redefines sealing performance through scientific formulation, transforming cutting-edge material technology into accessible solutions for users. Its comprehensive application coverage, military-grade durability standards, and minimalist operational logic not only significantly reduce maintenance costs and time but also redefine the industry’s understanding of “long-lasting sealing.” Hongfu will continue to drive innovation, delivering sealing products that exceed global user expectations and safeguarding every critical detail.

-

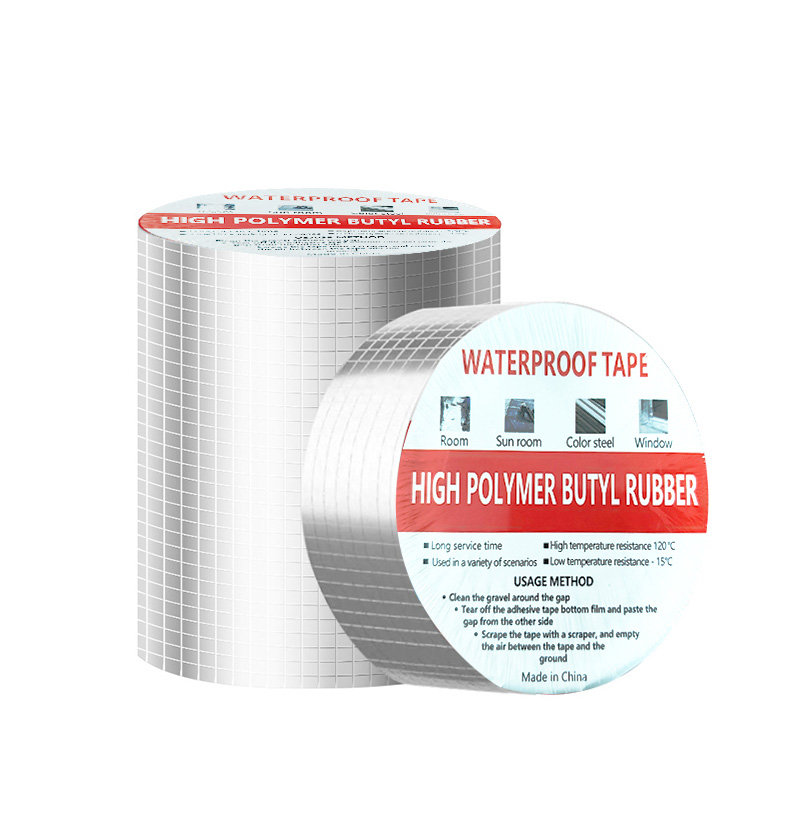

Suitable for various occasions

Roof

Glasshouse

Color steel sheet roofing

Sunroom

Roof ridge gap

Edge of the sink

The edge of the exterior window

Exterior wall cracks

-

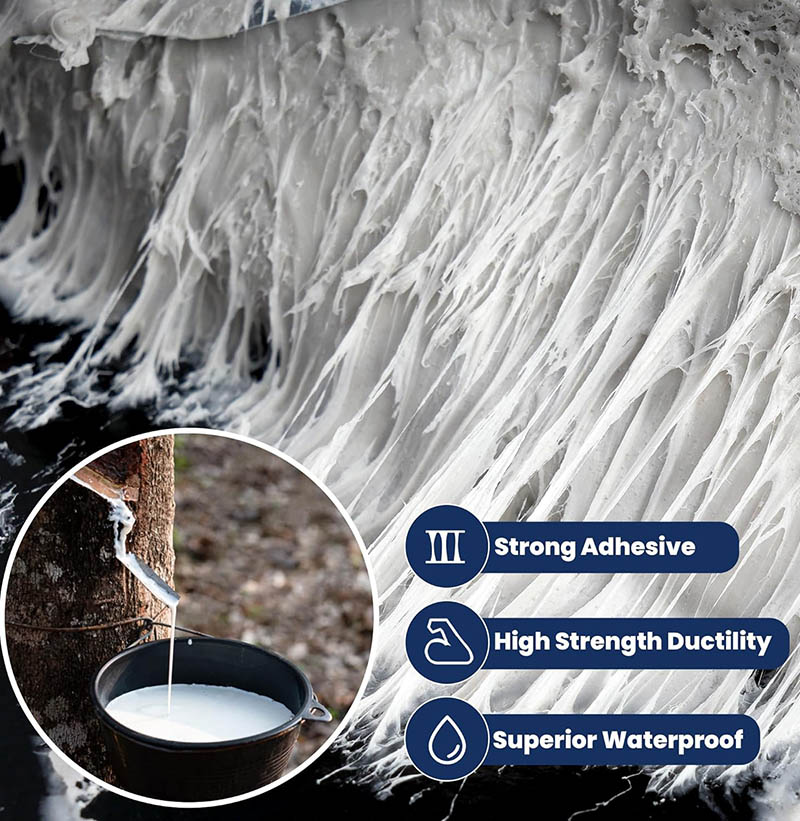

Strong Adhesive

High Strength Ductility

Superior Waterproof

-

Metal foil

Butyl rubber layer

Anti-stick liner

-

Product Features

Strong Adhesive

Waterproof

Toxic free

Extremely durable

Heat Resistant

UV Resistant

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

Technical Assistance

Billing and Payment Services

Why Choose Us?